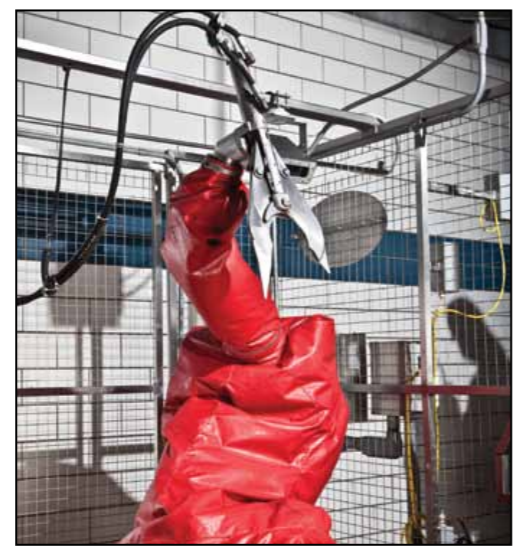

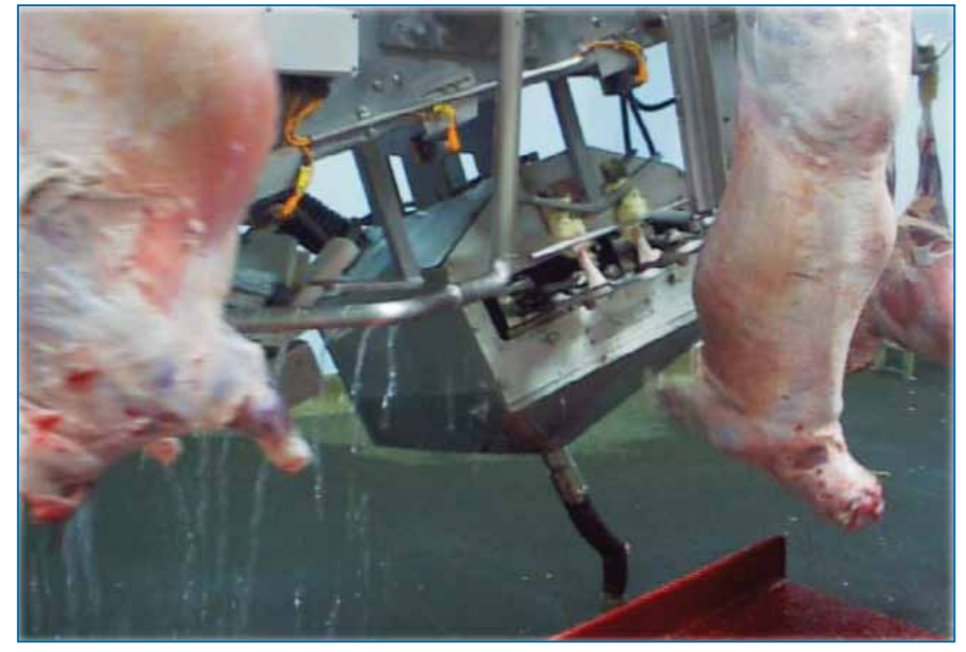

ROBOTIC HOG SPLITTER Model JR-165

ROBOTIC HOG SPLITTER Model JR-165

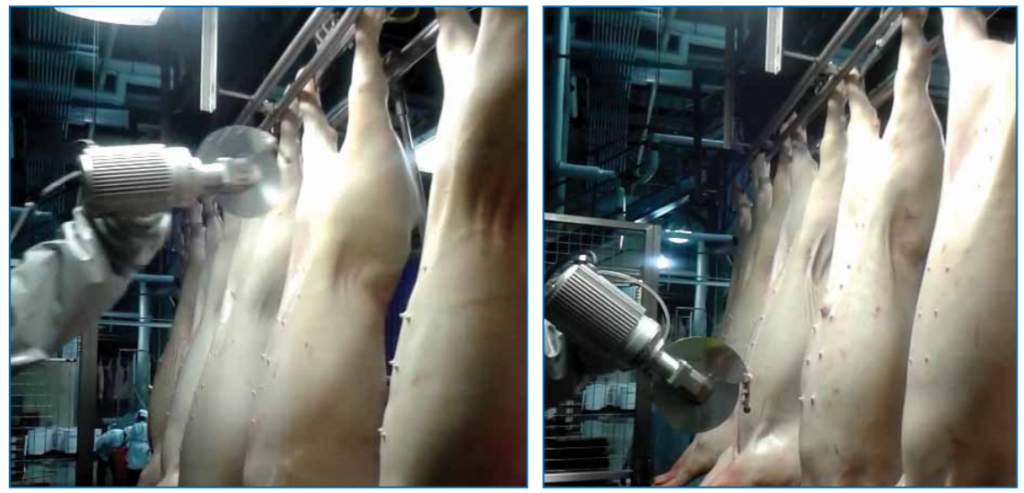

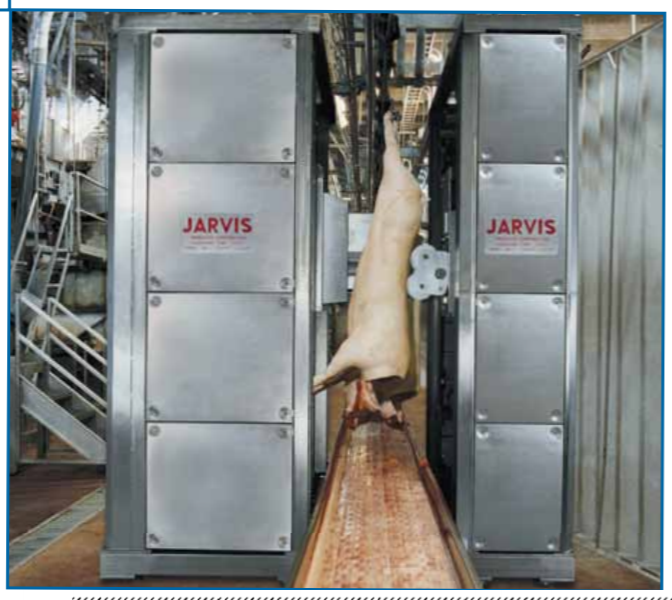

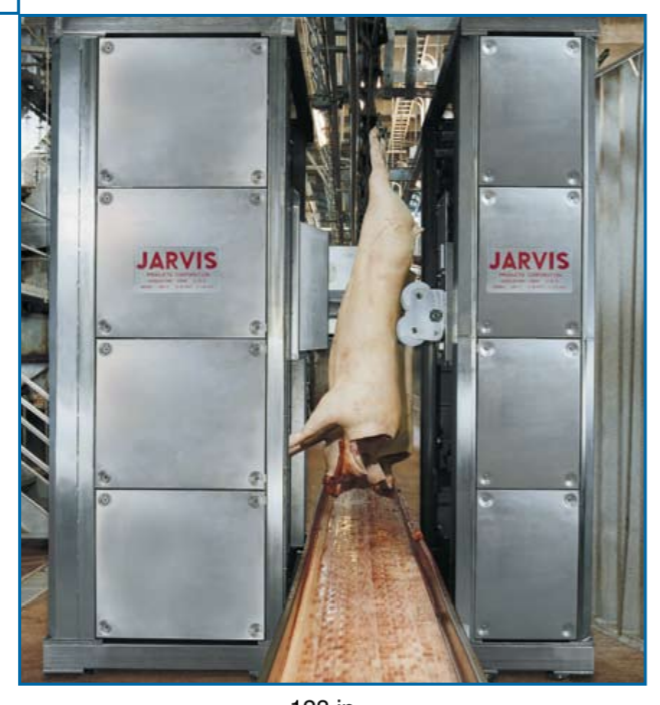

• Latest technology in robotic hog splitting, capable of 600 head per hour.

• High production rates and faster line operations.

• Uniform feather bone division.

• Higher amounts of speciality products.

• Remote diagnostics capability.

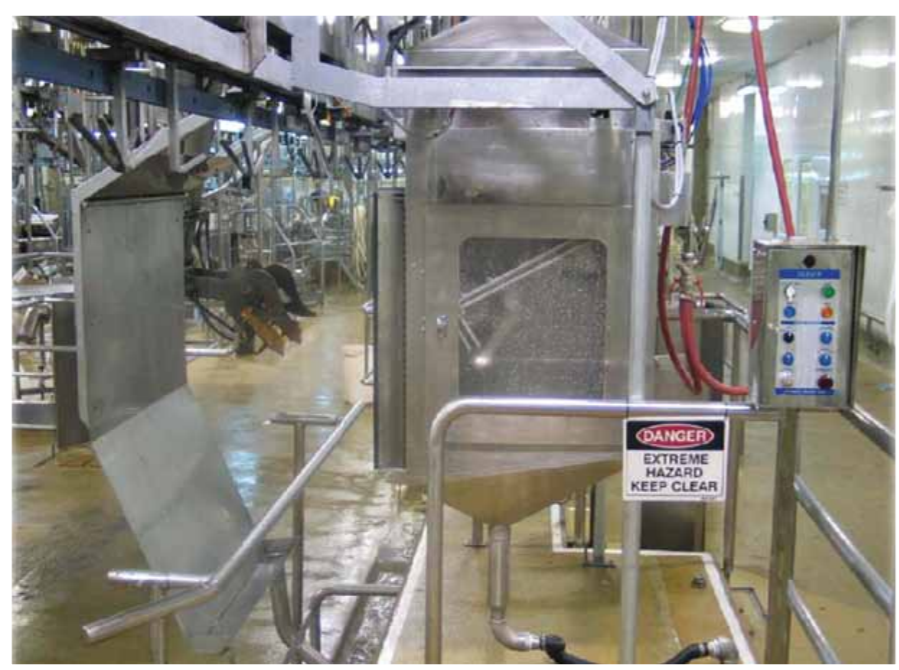

• Stainless steel base and a completely jacketed arm makes the JR-165 easy to clean and maintain.

• Adapts to any type of slaughter line.

• Longer saw blade life cycle.

• Installed anywhere on any production line, including close to corners.

• Automatic size adjustments for various sized carcasses – based on both weight or length