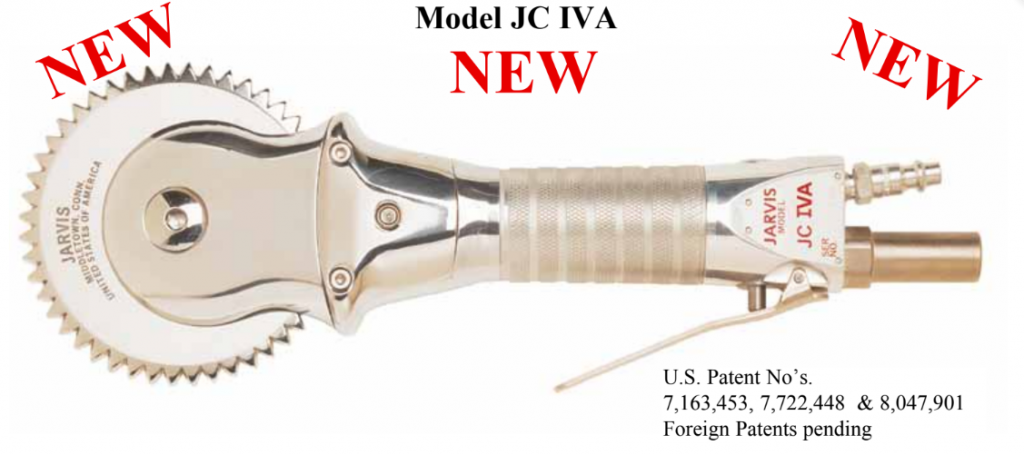

DEHIDER

DEHIDER

• Jarvis service technicians are available to provide FREE customer service, including equipment installation, service calls, and employee training.

• Constant torque air motor. Speed does not fluctuate due to air pressure change.

• Dynamically balanced drive mechanism for low vibration and reduced wear.

• Extra-thin head with stainless steel center plate for exceptional handling and strength.

• Skins perfectly, leaving no cuts, marks or holes.Produces highest possible quality hides.

• Lightweight – only 3.1 lbs (1.4 kg).