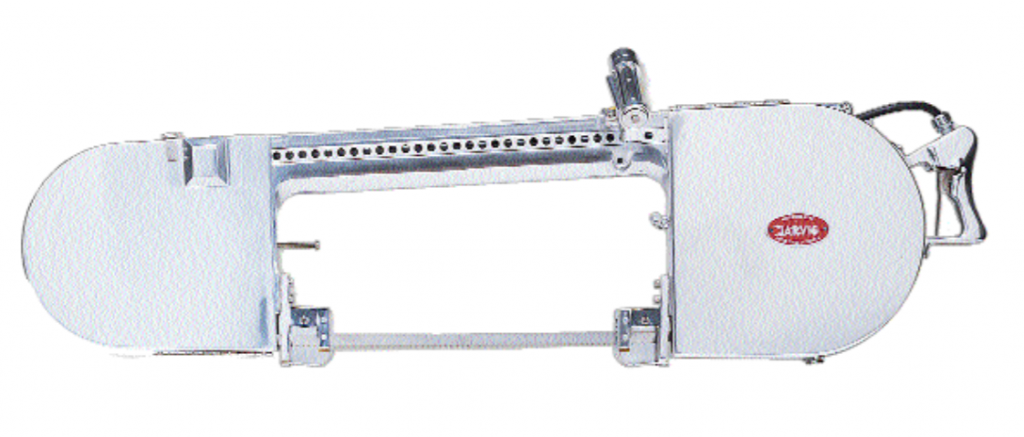

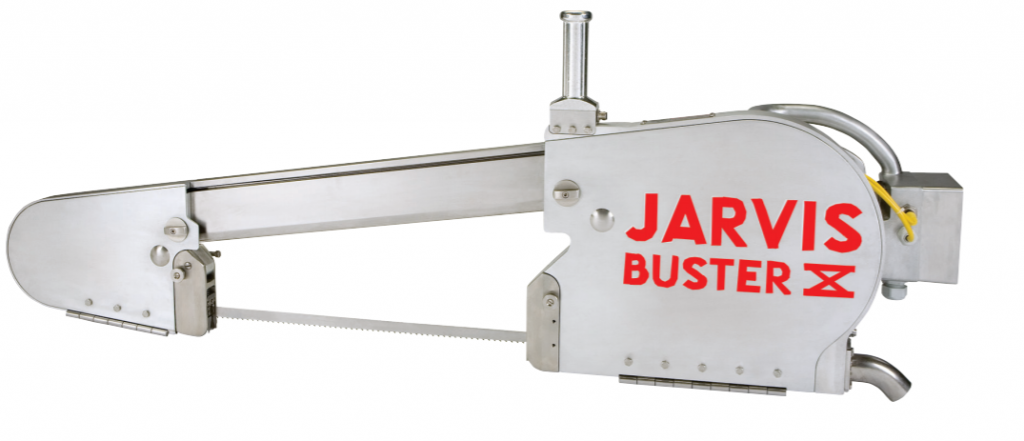

CARCASS SPLITTING BANDSAW Model H080

CARCASS SPLITTING BANDSAW Model H080

· Widely used for production pork splitting(up to 400 hogs / hour / saw).

· Economical, also suitable for beef and veal kills.

· Lightweight – less operator fatigue.

· Long blade life – 800 hogs per blade.

· Anti-tie down controls and totally enclosed electric motor for operator safety.