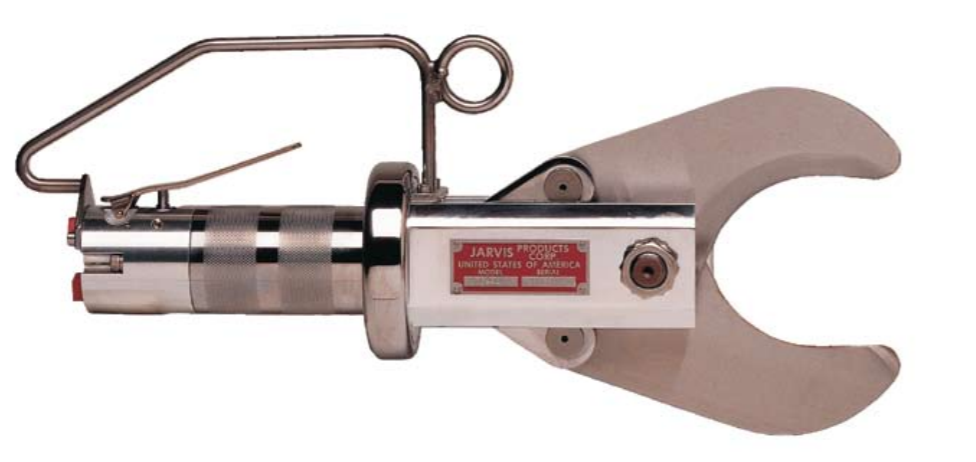

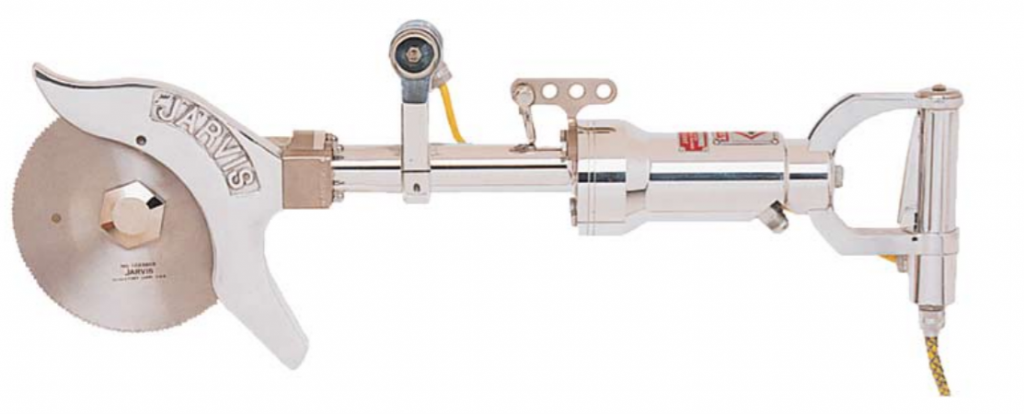

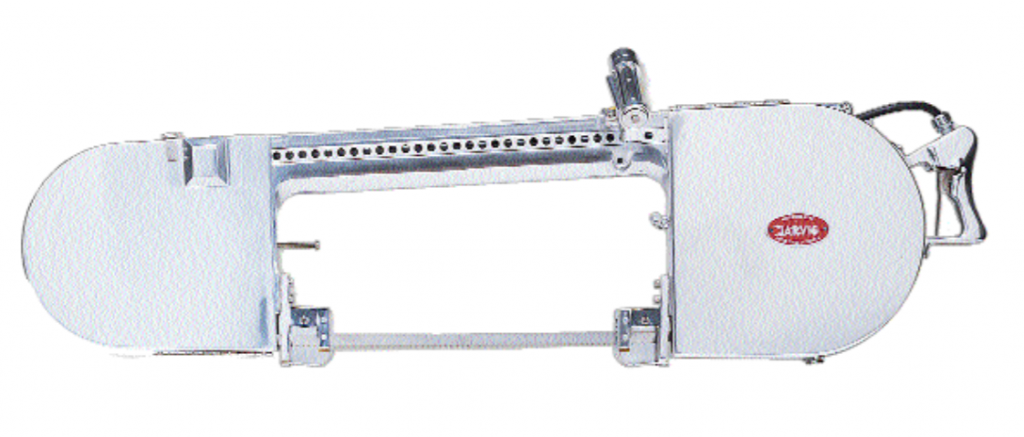

TOE AND HOCK CUTTER Model HTC-80 and HTC-110

TOE AND HOCK CUTTER Model HTC-80 and HTC-110

• Robust, powerful tool for removing hog and sow toes or feet as well as cutting hocks on calves and sheep.

• Blade opening (HTC-80) 3.15 inch (80 mm),(HTC-110) 4.42 inch (112 mm).

• Fast cutting, only 0.7 seconds per cut.

• Clean cutting – no splinters, no bone dust.

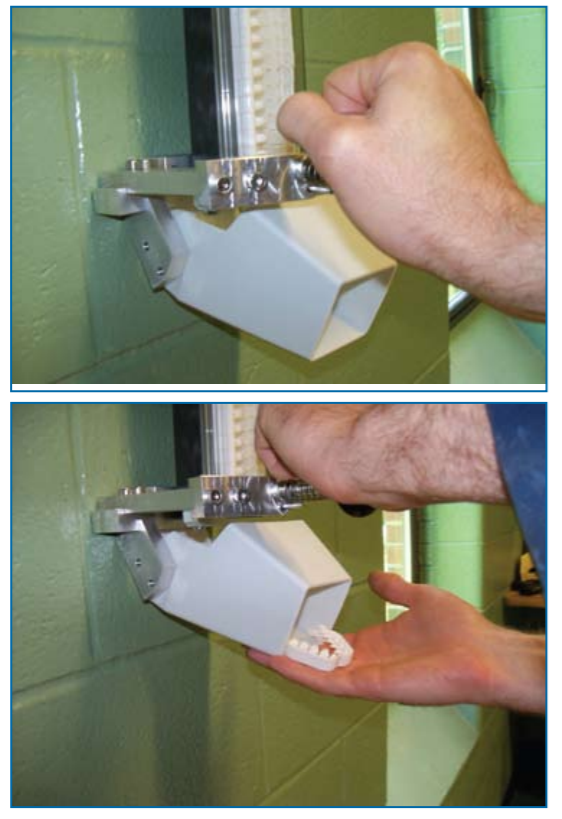

• Special hanger – the HTC-80/HTC-110 – can be used vertically or horizontally. Excellent in both positions; makes work easier.

• Blade guard is mountable on both sides for left or right handed operators.

• The HTC-80/HTC-110 is virtually maintenance free, for long trouble-free life.

• Lightweight – only 10.6 lbs / 4.8 kg (HTC-80), 11.5 lbs / 5.2 kg (HTC-110).

• Meets national and international requirements for safety and hygiene.